Essential Insights into Medical Device Regulation Compliance

In the complex world of medical device manufacturing, adhering to regulatory compliance is paramount. The Food and Drug Administration (FDA) sets stringent rules to ensure the safety and efficacy of medical devices. Here, we explore some common pitfalls companies often encounter and offer solutions to maintain compliance.

- Documentation Issues: Incomplete or poorly organized documentation is a frequent problem. This includes missing or outdated records, version control problems, and difficulty retrieving required files during inspections. To address this, companies should establish and maintain a robust documentation system, ensuring all records are up-to-date and easily accessible.

- Poor Quality Management System (QMS) Implementation: Companies often struggle to maintain a QMS that adapts to evolving regulations, engages all departments effectively, and balances speed to market with robust controls. To overcome this, companies should invest in a comprehensive QMS that is flexible and adaptable to regulatory changes.

- Failure to Keep Up with Changing Regulations: The FDA frequently updates its requirements, especially related to device safety, cybersecurity, software testing, and connectivity. To stay updated, companies should regularly review and update their policies and procedures to ensure compliance with the latest regulations.

- Misclassification of Devices: Incorrectly classifying medical devices can lead to regulatory delays or product detentions. To avoid this, companies should thoroughly understand the classification criteria for each device class and ensure accurate classification.

- Site or Facility Readiness Deficiencies: Even with correct product specifications, failing to have audit-ready manufacturing sites or unaddressed FDA inspection observations (483s) can cause regulatory setbacks. To prepare for audits, companies should regularly conduct internal audits and address any observed deficiencies promptly.

- Inadequate Product Testing and Justifications: Common pitfalls include missing data on extractables/leachables, incomplete compatibility or microbial integrity testing, insufficient stability data to support shelf-life claims, and weak validation of specifications and test methods. To address this, companies should ensure comprehensive and rigorous testing of their devices, including validation of testing methods and data analysis.

- Supplier Quality Variability: An inconsistent supplier quality system can jeopardize compliance since external inputs affect overall device quality and regulatory standing. To mitigate this, companies should establish and maintain strong relationships with their suppliers, ensuring they adhere to the same quality standards.

Companies must ensure robust documentation, maintain responsive and comprehensive QMS, keep abreast of evolving FDA regulations, correctly classify devices, maintain audit-ready facilities, validate all testing and data comprehensively, and control supplier quality to avoid these common compliance pitfalls.

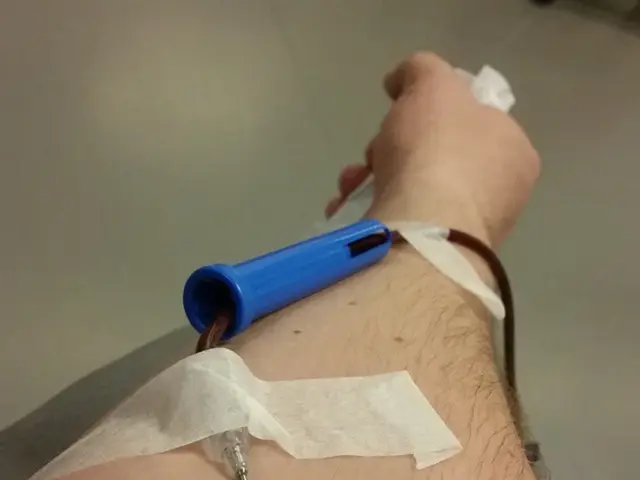

The FDA classifies medical devices into three classes: Class I, Class II, and Class III. Class I devices, such as a reflex hammer or bandage, are associated with low levels of risk. Class II devices, like diagnostic specimen kits, have moderate risk, while Class III devices, such as pacemakers, are associated with high levels of risk.

For new medical devices or major adjustments to existing ones, a 510(k) is required. Most Class II devices are non-exempt from this requirement, while most Class I devices are exempt. Most Class III devices require the Pre-Market Approval Program (PMA) due to the high-risks associated with them.

It is important to check if your device requires special labeling or other specific controls. Special controls may be required for Class II medical devices, such as special labeling requirements.

The Code of Federal Regulations states whether a medical device is required to have a 510(k) or if the device is exempt. Failing to create and follow written medical device reporting procedures is a violation of 21 CFR 803.17. Manufacturers are required to report any medical device incidents that cause serious injury or death or a malfunction that could lead to serious injury or death.

Device manufacturers, importers, and user facilities are required to report adverse events related to medical devices via the Medical Device Reporting program. Companies must also register their devices electronically before bringing them to market.

For companies seeking guidance on regulatory compliance, Sterling Medical Devices offers regulatory compliance consulting to help meet regulatory controls throughout the entire product development life cycle. By understanding and addressing these common compliance pitfalls, companies can ensure the safety and efficacy of their medical devices, ultimately benefiting patients and healthcare providers.

- Companies suffering from incomplete or chaotic documentation run the risk of non-compliance, as records need to be up-to-date, organized, and easily accessible during inspections.

- To avoid difficulties in implementing a Quality Management System (QMS) that adapts to changing regulations and balances speed to market with robust controls, companies should invest in a flexible and comprehensive QMS.

- Keeping up with the FDA's frequent updates on device safety, cybersecurity, software testing, and connectivity regulations is crucial to ensure ongoing compliance.

- Incorrect device classification can cause regulatory delays or product detentions, so it is essential to understand the device classification criteria and ensure accurate classification.

- To prevent issues during audits, companies must maintain clean manufacturing sites, address all FDA inspection observations, and perform regular internal audits.

- Companies should cross-check if their devices require special labeling, extra controls, or a 510(k) submission, as per the Code of Federal Regulations, and have written medical device reporting procedures to avoid violations of 21 CFR 803.17.

- Failing to conduct comprehensive and rigorous testing on devices, including validation of testing methods and data analysis, can lead to substandard products.

- To ensure consistent product quality, companies must establish strong relationships with their suppliers and verify that they adhere to the same quality standards.

- Device manufacturers, importers, and user facilities must report adverse events related to medical devices via the Medical Device Reporting program, and register their devices electronically prior to market release.

- To gain guidance on regulatory compliance for medical device manufacturing, companies can seek consultation from regulatory experts like Sterling Medical Devices throughout their product development life cycle.