Workplace Health and Safety: A Science-Based Approach to Ensuring a Healthy and Safe Environment at Industrial Sites

In the ever-evolving landscape of workplace safety, industrial hygiene is undergoing a significant digital transformation. This shift, driven by advancements in technology such as the Industrial Internet of Things (IIoT), artificial intelligence (AI), and real-time monitoring systems, is reshaping the way we protect employee health and safety.

Industrial hygiene, a scientific discipline focused on identifying, evaluating, and controlling workplace hazards, is moving away from traditional retrospective assessments towards proactive, data-driven hazard management systems. This evolution is crucial in addressing the complex and cumulative occupational risks that modern workplaces present.

### Key Trends in Digital Integration and Real-Time Monitoring in Industrial Hygiene

1. **Industrial IoT and Edge Computing:** The adoption of advanced edge computing allows for real-time data analysis directly at the source, enabling faster responses to potential hazards. This integration supports continuous monitoring and immediate intervention in workplace environments.

2. **Artificial Intelligence (AI) and Machine Learning (ML):** AI and ML technologies are being used to improve predictive capabilities and automate processes within industrial hygiene programs. These systems analyze complex data trends such as exposure to multiple hazards, enhancing decision-making and risk management.

3. **5G Connectivity:** The rollout of 5G technology facilitates seamless, low-latency communication between monitoring devices, enabling high-speed data transmission essential for real-time hazard detection and control.

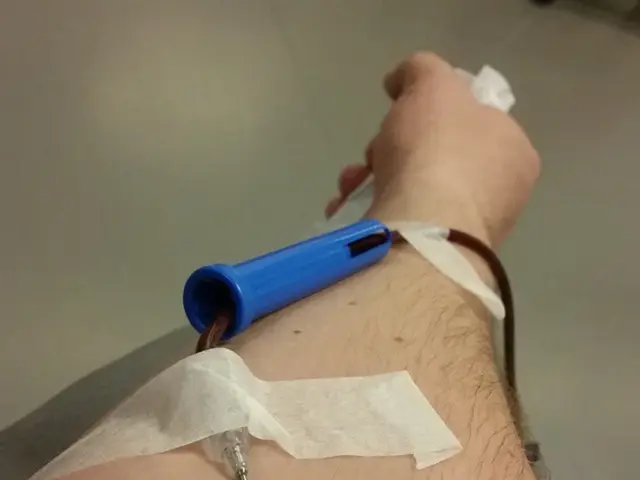

4. **Wearable Sensors and High-Tech Wearables:** Wearable devices equipped with sensors monitor workers’ posture, noise exposure, proximity to dangerous machinery, and cumulative exposure to airborne substances. These devices alert workers and management to unsafe conditions, improving safety compliance and preventive actions.

5. **Real-Time Environmental Monitoring:** Sensors are increasingly deployed to track airborne contaminants such as silica, formaldehyde, and volatile organic compounds (VOCs), aligning with tighter permissible exposure limits (PELs) and more comprehensive exposure assessments.

6. **Integration with Environmental, Social, and Governance (ESG) Reporting:** Industrial hygiene data is being integrated into ESG frameworks, supporting organizations in meeting regulatory and sustainability goals by transparently reporting workplace health and safety metrics.

7. **Biometric Technologies:** Contactless biometric systems (facial recognition, iris scanning, palm vein authentication) are being integrated with IoT to enhance secure access control and hygiene in sensitive industrial areas. This reduces contamination risk while maintaining strict security in manufacturing environments.

8. **Virtual Reality (VR) and Robotics for Training:** VR programs simulate hazardous scenarios for worker training, enhancing preparedness without exposing employees to actual risk. Robotics and automation reduce human exposure to dangerous tasks.

9. **Cloud Computing and Data Analytics:** Cloud platforms support aggregation, storage, and sharing of industrial hygiene data, facilitating remote monitoring and collaborative decision-making across organizational levels.

These technological advancements collectively enhance the ability of industrial hygienists to monitor worker exposures in real time, predict and prevent occupational illnesses, and streamline compliance with evolving safety standards.

---

### Summary Table: Key Digital and Real-Time Trends in Industrial Hygiene

| Trend/Advancement | Description | Benefits | |----------------------------------|---------------------------------------------------------------|-------------------------------------------| | Industrial IoT & Edge Computing | Real-time data processing at the source | Immediate hazard detection and response | | AI & Machine Learning | Predictive analytics and automation | Improved risk assessment and prevention | | 5G Connectivity | High-speed, low-latency device communication | Seamless real-time monitoring | | Wearable Sensors & High-Tech Wearables | Monitoring posture, noise, proximity, exposures | Enhanced worker safety alerts | | Real-Time Airborne Contaminant Monitoring | Continuous measurement of airborne hazards | Compliance with tighter exposure limits | | Integration with ESG Reporting | Linking hygiene data with sustainability criteria | Transparency and regulatory compliance | | Contactless Biometrics | Secure, hygienic access control | Reduced contamination and unauthorized access | | VR & Robotics for Training | Simulated hazard training and automation | Safer, more effective worker preparation | | Cloud Computing & Data Analytics | Centralized data storage and collaborative tools | Remote and informed decision-making |

These trends are transforming industrial hygiene from traditional retrospective assessments to proactive, data-driven hazard management systems that safeguard worker health more efficiently and accurately.

This digital evolution ensures industrial hygiene programs are better equipped to handle complex and cumulative occupational risks, fostering healthier workplaces and stronger compliance frameworks in line with 2025 standards.

The integration of technologies like Industrial IoT and edge computing in industrial hygiene allows for real-time data analysis at the source, enabling faster responses to potential hazards, boosting productivity and overall occupational safety.

The use of artificial intelligence (AI), machine learning (ML), and technologies such as virtual reality (VR) and robotics for training, not only enhances worker preparedness but also contributes to the health-and-wellness goals of organizations by reducing work-related injuries and improving overall safety.